Ive never noticed any. Welding magnetized drill pipe sucks.

Welding Magnetized Drill Pipe Sucks Welding

Tack welds around the weld joint.

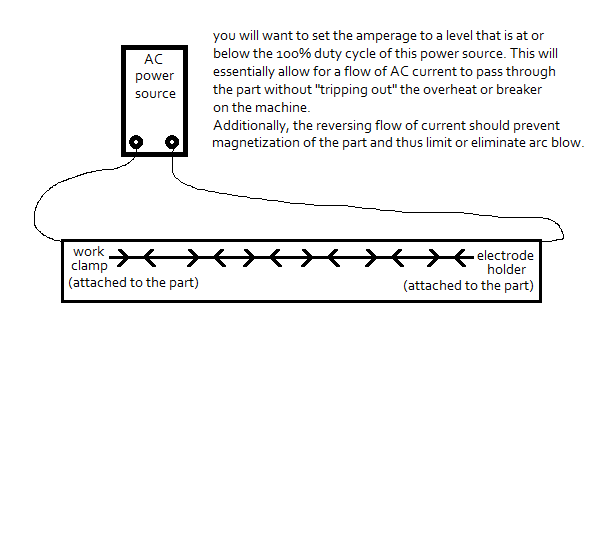

Welding magnetized drill pipe. The problem is that during normal use drill pipe acquires the properties of a permanent magnet. The effect is most pronounced in steels and although the magnetism in the material measured in air at the end of the pipe may only be a few tens of gauss after fit up the field becomes concentrated in the gap between the two pipes. Far as the magnetized pipe an easy way to counter it is an AC welding machine with 6011.

Also shifting your ground or wrapping your cables to counter the magnetic field sometimes works if AC is not available. What Is The Welding Process. If that doesnt work heat the weld zone to a dull red with a torch.

Moving forward or backward may make a difference. After the forging process the forged drill rods are then sent through a series of induction coils and a gas furnace for Austenitizing where the pipe is heated to 1650 degrees. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test.

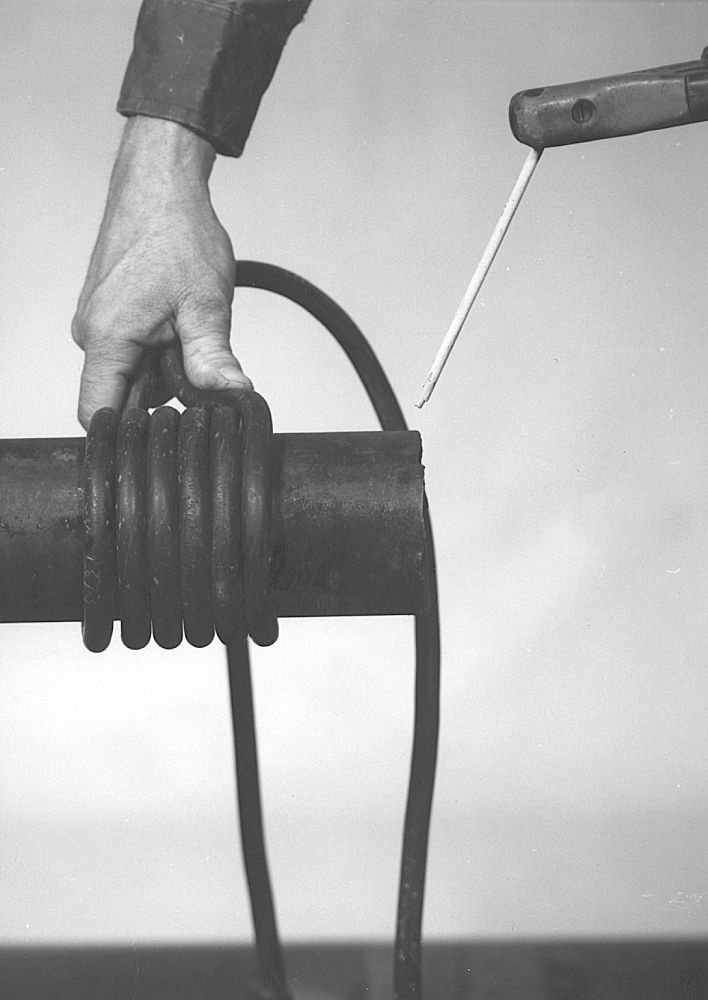

Using a current in the lower range of what. I wrap the lead around the pipe three to six times about half the pipe diameter away from the weld groove on the opposite side from the direction of the arc blow pull. Tip for welding extremely magnetized pipe and welder working in the oil field will face the dreaded mag pipe sooner or later and they will all stugle and fight it sware and throw there stinger and wish they werenot a welder for a bit and ive herd lots of ways of dealing with mag pipe and not one of them has worked for me.

More than likely you have high alloy or high carbon pipe. The effect of the magnetic field depends on the welding process but a good. And Canada used oil field drill pipe is cheap and easy to find.

The pipeline research committee of the American Gas Association had Proctor Inspection Consultants in Houston Texas do investigations into this. In many areas of the US. This can cause problems welding with DC so the usual easy fix is to use AC where the magnetism has little effect.

Ive spliced about a bazillion H-piles after being driven. With a DC only welding machine couple tricks. Nothing welded Nothing gained.

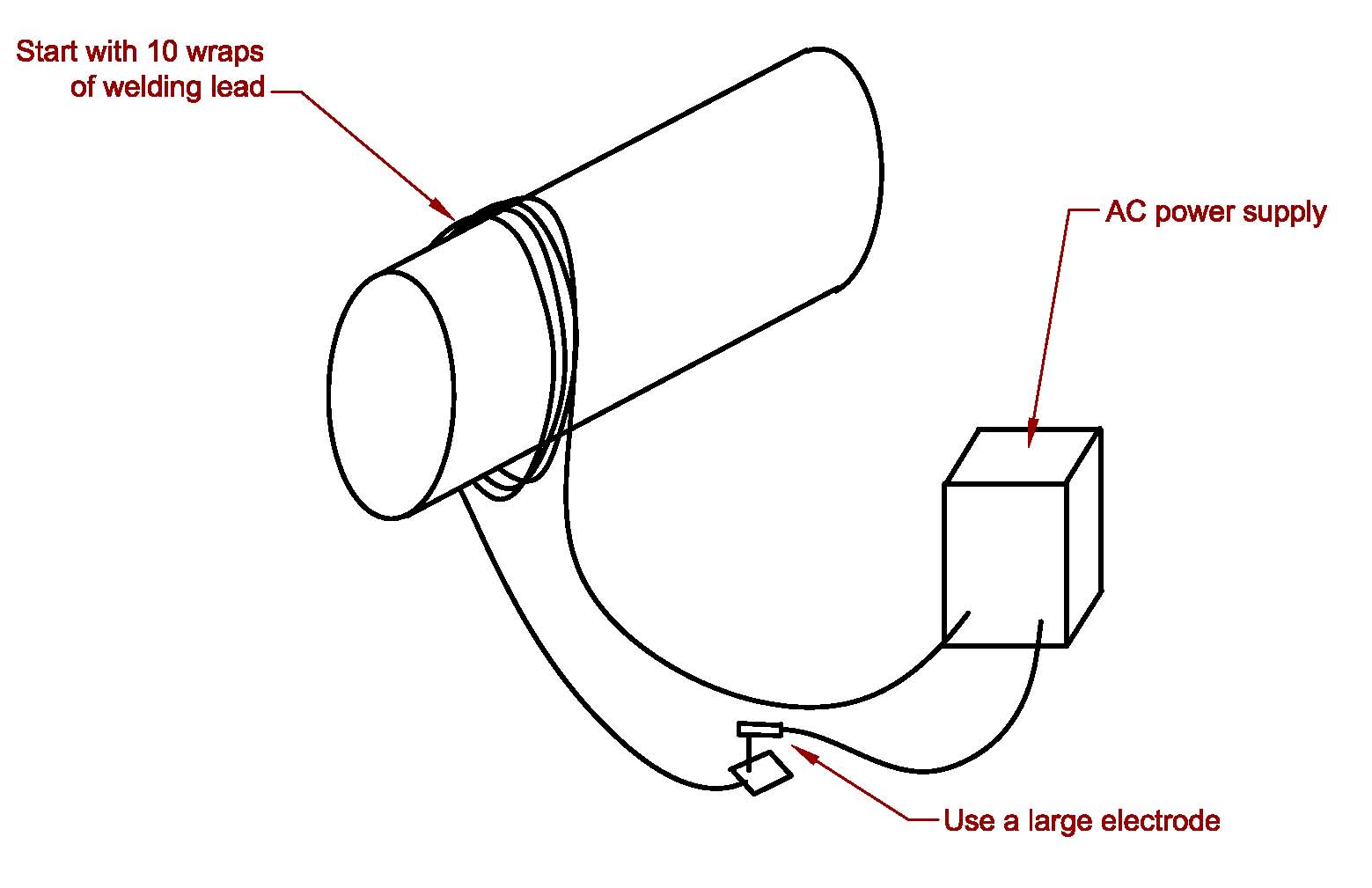

Demagnetizing a 30 inch 9 chrome pipe using AC welding powerWrap your pipe with one welding lead 6-10 times more is better direction doesnt matter as you. In this situation the field may reach 1000 gauss. This will induce a longitudinal field so that one end of the pipe is the North Pole and the other the South Pole.

My welder friends says that the drill stem is so magnetized it is nearly impossible to get the weld to hold. The strong magnetic fields at the ends cause the electric welding arc to sputter fluctuate and leap wildly from side to side of the joint making it difficult to get a good weld. And very difficult to weld with stick welder.

Welding magnetized drill pipe 01-07-2014 0804 AM I use 2 38 and 2 78 used pipe around the place and its magnetized and when i grind on it it makes worse. Drill stem or sucker rod is often magnetized frequently to the point where it will pick up small objects. A long welding lead protected to prevent arcing that is coiled or draped over the pipe circumference.

Remove the welding lead and check for. In this video John will cover the essentials on industrial pipe welding. Welding magnetized drill pipe sucks.

Keep in mind drill pipe is not standard pipe material due to the stresses it is subjected to. One common method that I have used on pipelines in the oil and gas industry is to create a magnetic coil with the work lead. This has been extensively documented by a number of studies by people and organizations.

Demagnetizing a 30 inch 9 chrome pipe using AC welding power. Try preheating the area to be welded without knowing specific chemical composition of the pipe a good starting point will be around 300 degrees F A higher preheat may be required again I doubt if magnetization is the source of cracking. At this point the steel is too hard for use on an HDD rig as it would crack due to how brittle it is.

Saved by Austin Wood and Metal. Magnetism and arc blow can cause welding problems when welding pipe particularly for pipelines. But welding it can sometimes be tricky.

Wrap your pipe with one welding lead 6-10 times more is better direction doesnt matter as. The strong magnetic fields at the ends cause the electric welding arc to sputter fluctuate and leap wildly from side to side of the joint making it difficult to get a good weld. The opposing magnetic field can be introduced by two methods.

The problem is that during normal use drill pipe acquires the properties of a permanent magnet. Were welding two 7 sections of drill pipe together thats going to be driven into the ground as piling to supports heavy staircases. Immediately upon exiting the Austenitizing furnace the pipe is quenched with a polymer based fluid to set the final microstructure which makes the steel very hard.

Using AC current causes the polarity of the magnetic field to change many times per second depending of the cycles used ie 60 Hz or 50Hz. If that doesnt work change directions of the wrapping. Once you have reduced the number of cable wraps to 1 wrap the welding lead around the pipe several times.

Never heard of that before. Welding magnetized drill pipe sucks. Then I deposit several ¾- to 1-in.

The pipe is heavily magnetized and were trying to get full penetration so it doesnt snap when its hammered. Once again energize the circuit. First thing Id do is wrap the ground lead around the pipe 4 or 5 times.

Start with a low setting and increase gradually after a few minutes. Welding Drill Articles Cooking. Using 6011 on dc it will just burn the rod up from sticking if i turn it to dc- it will weld.

Fundamentals Of Professional Welding

Farm Show Magazine The Best Stories About Made It Myself Shop Inventions Farming And Gardening Tips Time Saving Tricks The Best Farm Shop Hacks Diy Farm Projects Tips On Boosting Your Farm Income

Got This For Free Building A Fence How Do I Clean It If It Was Just Rust I D Sand Ospho But There S Quite A Bit Of Oil Grease On It Intend To

Http Www Westerninstruments Com Dec2016revisions Demag 20paper Pdf

More Magnetized Pipe Pipeline Video Youtube

How To Stick Weld Pipe Welding Tips And Tricks Advice Youtube

More Magnetized Pipe Pipeline Video Youtube

Http Www Westerninstruments Com Dec2016revisions Demag 20paper Pdf

Fundamentals Of Professional Welding

How To Strongly Magnetize Tools With Your Welder Shop Tips N Tricks I Forge Iron

.jpg)